Performance Tests

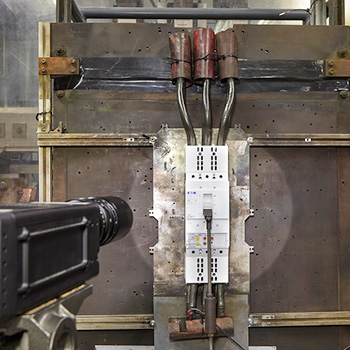

The use of state-of-the art analysis tools offers our customers a wide range of performance tests and analysis options for an extremely wide variety of components and devices. For instance, fast motion sequences can be examined with a high-speed video (HSV) camera. A high-resolution real-time X-ray inspection system enables us to visualize motions and structures inside enclosed components and devices visible.

|

The use of X-ray radiation for nondestructive macrostructure analyses makes it possible to look into a device or component and to obtain images of individual parts or assemblies in their installation position (even during operation) without influencing them. In addition to performance tests, X-ray inspections have also proven to be an invaluable tool in failure analyses.

Combining X-ray inspections with a high-speed video system (HSX), I2PS offers the option of recording fast processes inside a device during its operation. For later analysis an evaluations, these processes can replayed slowed down (e.g., switching operations in electromechanical switchgear).

|

Relevant Standards: In addition to customer-specific specifications, various national and international standards such as DIN EN 12681 Depends on the application and the requirements. Devices, assemblies, components |

|

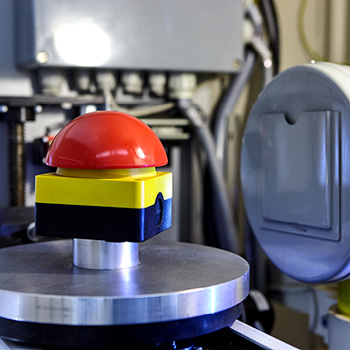

The ability to record operations and technical processes of any type with a high-speed video (HSV) system makes it possible to record extremely fast processes with frame rates up to 250,000 frames per second (depending on the resolution) and then replayed in slow motion for further analysis. Among other applications, this system is used in the analysis of electrical switching operations and arcing characteristics (short-circuit tests, tripping behavior, performance tests, etc.). Moreover, it is also common practice to analyze motions under diverse mechanical stress. High-speed video recordings can also be carried out during X-ray inspections in order to visualize and test fast-running internal processes (HSX). All in all, these methods can be used for an extremely wide variety of products and applications. With our mobile equipment we also can carry out recordings on-site. Simply call us – we will help you with your specific application.

|

Relevant Standards: |